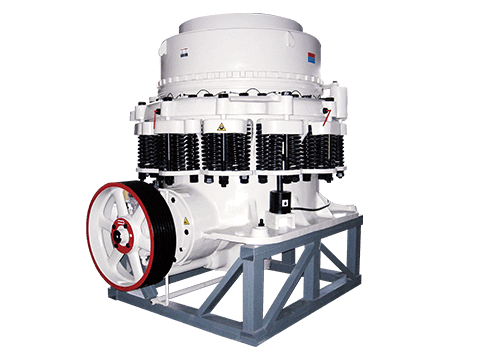

Some Basic Information of Spring Cone Crusher

Spring cone crusher is suitable for crushing various of mid-hard ores and rocks. This crusher has the advantages of reliable construction, high productivity, easy adjustment and less cost in operation. The spring release system of crusher acts an overload protection system that allows tramp to pass through the chamber without damage the crusher, use dry oil, water, two kinds of sealed formation. It made plaster stone and engine oil seprated, assured reliable performance,the type of crushing chamber depends upon the size of feed and fineness of the crushed product. The standard type is applied to medium crushing , the medium type is applied to medium or fine crushing and the short head is applied to fine crushing.

The Main Features of Spring Cone Crusher

1.high efficiency and better quality

2.provid a spring type protection device

3.reasonable structual and easy to adjust

4.easy adjust the particle size of crushing and discharging

The Working Principle of Spring Cone Crusher

Cone crusher crushes materials by the working surface between the movable cone and fixed cone. So it is more advanced and efficient than jaw crusher. The movable cone is supported by spherical bearing and fixed on an hanging erect shaft which is set in the eccentric sleeve, and the sleeve is set on the stopping and pushing bearing. The movable cone and erect shaft are driven by the eccentric shaft sleeve together. The eccentric shaft sleeve is driven by horizontal shaft and fimbriated gear, and the wheel of the conveyor belt is driven by motor through v-belts. The lower part of vertical shaft is installed in the eccentric sleeve. When the eccentric sleeve rotates, there is a conical surface lined out by the shaft. When the movable cone comes near the fixed cone, rocks are grinded into pieces, when the movable cone leaves, grinded materials is discharged from the discharge hole. The fixed cone can be ascended or descended by adjusting setting to adjust the width of discharge hole, consequently the output size is determined adjusted.

It can crush more than 100 kinds of rocks. The common discharge size is...

8618538065701

8618538065701

Chat Online

Chat Online Get Price

Get Price